Seasonality and Inventory Management

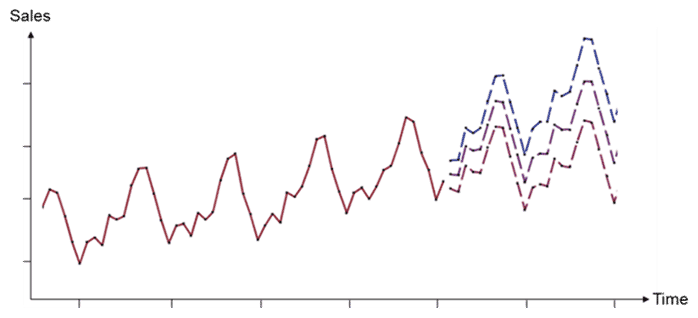

Demand seasonality is generally associated with a boost in sales that occur at specific times of the year, e.g. Black Friday and Back-to-School (BTS). These cyclic patterns play an important role in supply chain management, and can make it challenging for businesses to accurately plan inventory levels. The degree of seasonality (i.e. the scale of seasonal change combined with the consistency of the variation), will influence the level of inventory planning required.

In retail strategy, seasonal events are key factors of inventory control, and despite their repetitive nature, it can be difficult to judge the right amount of inventory to meet demand. This is especially true since each surge is usually accompanied by an abrupt reduction in demand!

Predictions often lead to over and under-estimations and so, finding that symmetry between lost sales and inventory costs can be tricky.

Black Friday

Often described as a retail phenomenon, Black Friday has, in recent years, been adopted globally and expanded beyond a single-day sales event. For many retailers, this is the most important event of the year. Following the rise of online shopping, Cyber Monday is now considered part of this shopping extravaganza.

Similar to seasonal inventory, supply chain planning for upcoming deals can be challenging. Stocking-out of popular products can result in lost sales (typically, stockouts drive consumers towards the competition) and can easily obliterate consumer satisfaction. On the other hand, excess and idle stock can strain working capital, contribute to operational losses, and eventually lead to obsolescence.

The challenge, therefore, is in determining the best order quantities and this requires careful planning and balance to prevent running into either scenario.

Back to school

Just like the Black Friday boost, the BTS season is one of retail’s coveted seasons that is characterised by a longer shopping wave. In the past few years, consumption behaviour has changed. Most of us have seen the needs of students gradually shift from basic stationery products (pens, notebooks, etc.), to hardware such as laptops, tablets, USB drives, etc., all of which are now regarded as essential. This extended sales window and product profile introduces challenges for the retail supply chain during the BTS season.

Although the event is timed to align with school re-openings, retailers generally activate promotional offers in late July. Indeed, many adjust their buying schedules to bring in stock earlier. This allows the time for consumers to research products (footwear, school supplies, apparel, and electronics). It also allows brands to make their purchasing decisions before schools reopen. In fact, BTS shopping usually prevails throughout November.

Some analysts expected BTS demand to be heavy this year and, as students adapt from virtual to in-person learning. While COVID-19 cases remain in flux, in-store shopping is anticipated to reduce from last year while online shopping will significantly influence BTS shoppers.

It is also expected that, in comparison to previous years, fewer choices will be available to the consumer on account of low supply across several categories. Further, since availability for some products is scarce, retailers may have little incentive to discount prices in order to sell. All of these challenges combined may result in fewer BTS deals this year.

Clearly, consumption data within the past 18 months is atypical and so, demand in 2021 is not as predictive as one would expect and even at this writing, the supply chain remains disrupted. Despite vaccination efforts, the pandemic continues to affect global manufacturing capacities. While alternative sourcing options are pursued, port congestion continues to disturb the flow of imports.

When one also considers that, in many cases, stock currently on shelves was planned by retailers last year when there were fewer purchasing insights available, then it is easy to appreciate why retailers face unprecedented difficulties in predicting demand for this year’s BTS season.

Managing stock levels

Although adequate stock levels depend on the nature of your business, there are still some practices that can help avoid lost sales and excess inventory.

- Many planning decisions remain guided by management intuition and experiences. However, handling a large SKU portfolio in this way becomes overwhelming and this is where an automated replenishment model can be indispensable. Such a tool does not need to be sophisticated (it may be constructed in Excel©) and can be readily tailored to your business profiles and product attributes. This, combined with your current inventory data, can improve your analytical efficiency. Such efficiency allows you to make sense of the data and position the right amount of stock in the right place at the right time.

- Since seasonal inventory can be very unpredictable, your business forecasts should account for seasonality to ensure that sufficient stock is on-hand to meet peak demand. Then, once the season is over, the risk of overstocking is minimised.Often, we find that reorder point models assume demand to be stationary – without regard for fluctuating behaviour. Nonetheless, demand during the lead time is influenced by seasonal variations. It is therefore important to take this into account when evaluating the reorder point, even in situations where the degree of seasonality is low.Similarly, in calculating order quantities and safety stocks, variational effects become significant in cases where the degree of seasonality is high.

- Typically, high-performing retailers have one centralised inventory system controlled by a single instance of software running across all locations. This enables them to be instantly informed on product details, stock position and location.Strong omni capabilities also gives flexibility to connect demand to supply irrespective of the supply and demand locations. The shift in consumer shopping patterns is motivation to consolidate stock and facilitate the movement of products from in-store to online channels. Of course, all this will require you to have strong supply chain performance and operational prowess. A unified stock management system will give you the ability to monitor stock in real-time, permitting your BTS consumers to conveniently seek products online. Consumers will often then visit their nearest store location for the purchase to be completed in person.

- The alternative to having real-time stock visibility is to retain a safety stock policy. However, as discussed earlier, safety stock levels are sensitive to the variability of demand and supply lead times. In addition, depending on the product’s statistical profile, estimates can lead to overstocking which may eventually result in you having to mark-down those SKUs.

- More efficient planning tailored to BTS preferences requires the use of retail analytics. This enables you to move to data-driven insights, monitor online transactions, and to be constantly aware of price comparisons and competitive trends.

- Sales forecasts are generally derived using regression techniques and while accuracy is not necessarily expected (but always welcomed!), they are useful in providing insights into past purchasing behaviours. For seasonality, many practitioners first identify which products are likely to be affected by seasonal demand and then, they determine the timing of peak consumption. Next, by combining forecast data and actual consumption rates, it is possible to extract the relative size of those peaks at an item level.Before triggering the purchase order, you should evaluate the level of uncertainty or establish the confidence interval that is associated with each forecasted peak. Furthermore, it is easy to forget the importance of preparing your suppliers for seasonal demand fluctuations and throughout this process. It is therefore best to remain in close contact with your supply base and ensure each supplier has visibility of your needs, along with sufficient time to react and respond to potential changes.

- Finally, retaining slow-moving stock can restrict your opportunity to purchase faster-moving products. Prior to any seasonal event, consider disposing of unwanted/dead stock as this will provide precious storage space you require for incoming stock, and will help you minimise forward holding costs.

If you would like to understand more about how these principles can help improve your inventory planning processes, simply get in touch with us.

Supply Chain Enabled