Traditionally, it was believed that a high level of stock guaranteed a successful service performance for a company. Nowadays, we have seen consumer demand influenced by many factors (environmental conditions, economic, social, etc.), consequently making supply chains more dynamic than ever.

Furthermore, supply chain practitioners are now acutely aware that either over or under-stocking is both financially and operationally inefficient. In fact, recent history has witnessed a growing interest in the positioning of stock to meet targeted service requirements at the lowest possible cost. In response, many businesses have adopted optimisation principles to drive more efficient supply chains to keep inventory levels in check while protecting service commitments.

Demand Structure

In order fulfilment, purchasing decisions are generally made at the item / SKU level and, for the most part, each item has its own underlying demand structure that can have significant implications for both inventory and service. Syntetos et al. (2005) considered two key components that influence demand behaviour: namely, demand size and demand occurrence. Using the information on demand variation and the expected interval between transactions, they developed an influential framework to classify demand into four basic types; and these are: Smooth, Erratic, Intermittent, and Lumpy.

It is now recognised that basic stock policies perform rather poorly when demand is non-Smooth, making new approaches necessary for supply chain optimisation. Using this scheme, the replenishment model can be matched to the demand behaviour of any SKU, and this can help facilitate decision-making and allow planners to optimally tune inventory levels and service performance.

Replenishment Methods

Fundamentally, there are two main decisions common to all planning models; how much and when to order, and the choice of planning method largely depends on how often stock levels are checked. For random demand, stock levels are either reviewed continuously or periodically.

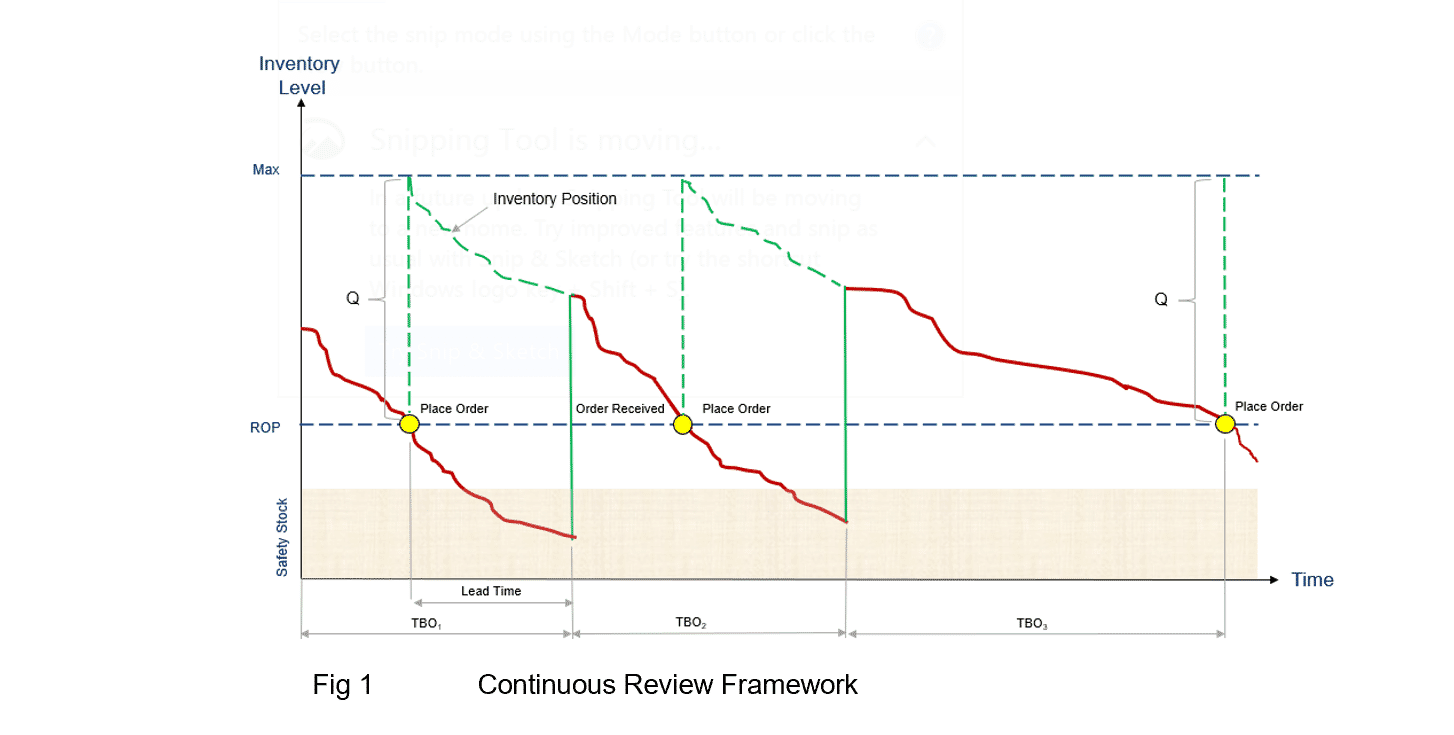

i. In a Continuous Review framework, the stock level is constantly tracked and an order for a certain lot size is placed when the inventory level declines to the specified reorder point. Generally, the size of the order remains fixed from one order to the next; however, the time between orders may change (given variable demand). The cycle then repeats, and the inventory profile gently fluctuates between the lower and upper limits while the stock rotates satisfactorily (Fig 1).

ii. In Periodic Review policies, inventory levels are assessed at specified intervals of time and an order is generated for a quantity of stock that moves the inventory position to the order up-to level. The order is subsequently received into stock, and after a fixed interval of time, a second review occurs to activate another replenishment and the cycle propagates. Depending on the demand experienced between successive orders, the order size may vary.

In any case, irrespective of the review method and the demand characteristics, given the desired service performance, our goal is to estimate the values of the key control parameters for optimal supply chain execution.

Service Performance

Broadly speaking, the availability of stock drives customer service. Fill Rate and Cycle Service Level are two common tools used to determine how effectively customer needs are fulfilled.

Despite being commonplace, we frequently find these metrics have many interpretations across industries and are often confused and interchanged. Nevertheless, the main goal of an effective service metric is to help avoid stockouts and promote customer satisfaction.

Formally, the (cycle) service level tells us the expected probability of not stocking out during the next replenishment cycle. So, for example – a 90% service level means that we must fulfil a customer request nine times out of ten. On the other hand, the fill rate represents the percentage of demand that we can fulfil. In the same way, if the customer demand is for 100 items, and we serve 90, then the fill rate performance is 90%.

Selecting a target service level or fill rate is a strategic decision that is often difficult to make. Target setting always involves inventory risk management and the choices are influenced by several factors including the current service performance, the impact of shortages on your customers, your competitive position, replenishment lead times, and so on.

Even today, there is a common misunderstanding regarding service level – the expectation that the service target should be 100%. In general, higher service levels require (exponentially) increasing levels of safety stock, and, aside from the greater carrying costs, the risk of inventory obsolescence also grows. Besides this, shooting for a 100% service level requires an absurd (strictly, infinite) quantity of stock.

So clearly, service is a trade-off between the cost of inventory and the cost of not serving your customers, and this is how you can decide what a good service level of fill rate is for you. Many ERPs contain a utility that triggers reorders for any given service level; however, in practice, we find that these often require manual interventions and offline processes to control replenishment.

Since quantitative measurements are now considered essential to optimal inventory and service performance (and despite the simplicity of these service metrics), you will find that they have their roots in historic performances and are often difficult to apply. What is more, when it comes to shortages or stockouts, they certainly do not reflect the degree of pain inflicted on the customer.

So, we would encourage you to consider an alternative two-fold approach; that is, to match your replenishment model(s) to your demand profiles and establish the economic drivers that influence your ordering decisions. These concepts will be discussed further next month, in the meantime please reach out to discuss your inventory needs.

Supply Chain Enabled