Businesses today are challenged to maintain pace with economic and market conditions and ever-changing customer behaviour. In response, warehouse technologies have become more complex, while warehouse managers continue to promote robotic adoption and innovation to improve labour productivity, delivery times, employee safety, and supply chain resiliency.

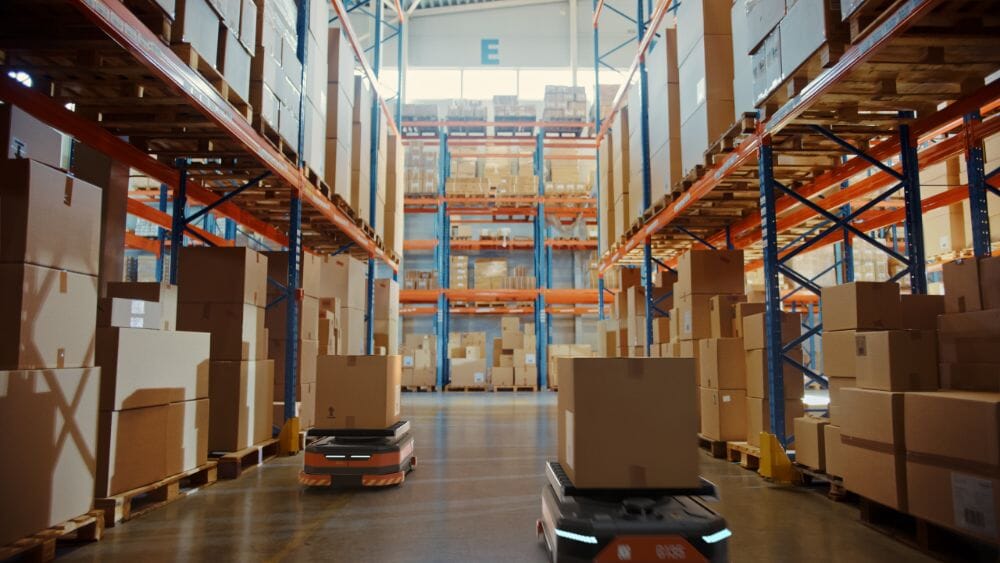

Fundamentally, the purpose of warehouse robots is to automate the flow of goods and increase productivity. These devices perform key warehouse tasks (e.g., receipt of goods, transferring items across locations, storing products, etc.) and can either work collaboratively with warehouse operators or autonomously.

In this three-part series, we explore how businesses have integrated automation into the logistics industry and, in particular, how and why warehouse robotics has gained importance in recent years.

The Evolution of Warehouse Robotics

The history of industrial robotics is largely credited to George Devol, who (together with Joseph Engelberger) developed the world’s first industrial robotic arm, the Unimate, which, in 1961, was installed at General Motors to assist the die-casting process. Eight years earlier, A.M. Barrett Jr. introduced the Guide-O-Matic, a modified driverless vehicle guided by an overhead wire. This was the precursor to the so-called Automatic Guided Vehicle (AGV), and shortly afterwards, guide wires were embedded in the floor to aid workers in moving heavy goods around a grocery warehouse.

Since then, the applications for robotics have grown enormously, and according to the International Federation of Robotics1 (IFR), “Robots in logistics are still the growth drivers” and the year-on-year growth is expected to be around 30%.

While the history of warehouse automation2 is relatively short, the combination of economic factors (especially the growth in e-commerce, tight labour markets, and supply chain uncertainties) has helped robotics advance. Interestingly, since the 2008 downturn in automotive manufacturing, automation innovators were compelled to concentrate efforts on non-automotive markets; among these were logistics and warehousing companies requiring intelligent robotics with capabilities to perform material handling and palletizing tasks.

It is also worth remembering that although e-commerce was an early adopter of warehouse automation, the growth of this market does not only impact e-commerce warehouses but also downstream warehouses. For context, the Shenzhen-based office supply specialist, Comix Group, deploys Geek+ warehouse robotics and has referred to a fragmentation and randomisation of e-commerce orders as more of their customers switch to online purchases while a growing number prefer to receive smaller shipments.

In the early days, robots were simply anchored to the warehouse floor and programmed to perform simple tasks using only basic motions. However, as sensor technologies advanced and computing hardware became more affordable, warehouse robots gained articulation and integrated image recognition capabilities, thus providing a first step towards autonomy. According to a report by Statista3, the logistics industry purchased 158,000 warehouse robots in 2021, and in 2023, this number is expected to grow to 250,000.

Warehouse Operations

Many tasks in warehouses and fulfilment centres generally involve material handling, and these range from container handling to order picking and packing. By their very nature, warehouse duties generally require operators to lift, stretch, bend, and walk while sometimes carrying heavy items, and it is easy to understand that (over time) this can impose repetitive strain on the body. Today, robots can work with warehouse management software to navigate the work floor, reduce the physical burden on operators, and ultimately lead to less demanding operations and faster order fulfillment.

Suppose, for instance, that demand for certain stocked products suddenly intensifies. A WMS can detect such abrupt changes in real time and, in response, direct connected robots to relocate the associated SKUs closer to the despatch door to minimise the order picking walking distance4. So, by dynamically relocating products according to their popularity, fulfilment centres can reduce their order pick cycle time.

Warehouse Robotics Systems

The above example is one of many, and you will find that there are now several kinds of robots specialising in a variety of warehouse-related tasks, which range from checking stock levels to the physical movement of goods within the facility. In the majority of today’s warehouses, most robots perform only one function (a robot designed for order picking will not be used to transport products, for instance); however, companies are now experimenting with multipurpose robots, which will enable businesses to install one robot for multiple tasks. Let us now take a look at the basic types of robotics available to the warehousing industry.

- Automated Guided Vehicles (AGV)

These vehicles carry loads by following a prescribed path around a warehouse facility using embedded markers or advanced LiDAR5. They are effective alternatives to carts or forklifts.

- Autonomous Mobile Robots (AMR)

These are very efficient transportation systems that create their own routes and navigate intelligently around obstacles in a warehouse using LiDAR, infrared sensors, or onboard cameras

- Aerial Drones

Small in size and moving with high speed and manoeuvrability, these devices are ideal for scanning physical goods in storage as they can fly to a racking location, estimate the storage quantity, and automatically update the inventory management system

- Unmanned Aerial Vehicles (UAV)

These perform the same tasks as aerial drones and are not autonomous but manually controlled

- Automated Guided Carts (AGC)

Similar to an AGV, these robotic vehicles are designed to carry smaller payloads

- Automated Storage & Retrieval Systems (AS/RS)

This warehouse automation is designed to buffer, store, and retrieve stock on demand. The technology varies substantially and generally consists of shuttles, cranes, aisles, AMRs, carousels, etc.

- Collaborative Robots (Cobots)

These robots have advanced sensory capabilities and are designed for close-proximity operator interactions. Many are programmed to follow operators along a path as they pick orders, while others work autonomously in areas populated by warehouse personnel.

- Articulated Robotic Arms

These robots are transportable and have rotary joints and specialised end-effectors that are designed to pick, pack, and assemble components, unload containers, or construct pallets

- Goods-to-Person (G2P)

This automation solution enables products to be taken directly to an operator by a fixed or mobile robot. Operators receive the items needed to prepare an order at their pick stations without having to move in any meaningful way from their location.

In part two, we will explore robotic systems in more detail and review use cases for each key warehouse function (i.e., loading and unloading, order picking, sortation, palletizing and depalletizing, packing, transportation, stock validation, and inventory replenishment).

Footnotes

[1] A professional non-profit organisation established in 1987 to promote, strengthen, and protect the worldwide robotics industry

[2] The terms robotics and automation are often interchanged, and although the two concepts are closely related, they are independent of each other. Robotics is just one way to automate a process, but automation is also possible without robots.

[3] A German online platform specialising in data gathering and visualisation that offers statistics and reports, market, and consumer insights

[4] Also known as slotting, the process of organising warehouse storage capacity to maximise efficiency

[5] A remote sensing technology that uses pulsed laser light to measure ranges

Supply Chain Enabled